Extrusion Services

Why Extrusion?

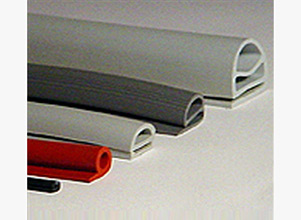

Extrusion is an excellent method of producing rubber when the desired end product can be run in continuous lengths of the same cross sectional profile.

Ames Rubber Manufacturing has a very versatile and wide range of extrusion capabilities. Small custom orders as well as large volume orders can be produced with a surprisingly short lead time. In fact, many standard O-ring cord orders can be shipped the same day they are received. Whether you require a custom profile with a specialized compound, or just some standard EPDM cable jacket, let Ames Rubber Manufacturing be your one stop solution for rubber extrusion.

Extruding can often be combined with other secondary fabrication processes such as: Cutting to length, printing & marking, punching holes, die-cutting notches, vulcanizing, and post extrusion molding and splicing, making it a cost effective alternative to rubber molding in many cases.

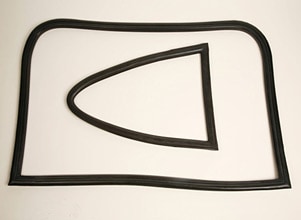

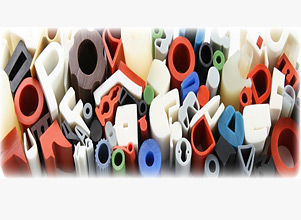

Extruded Profiles

Ames Rubber Manufacturing provides Extruded Polymer Solutions in a variety of custom rubber profiles, including:

Round Cord

Tubing

Radius "U" Channels

Square "U" Channels

"D" Seals

Half Round

P Seals

e Channels

Bulb & Channels

Tadpole Seals

Glazing Seals

Wing Bumpers

Hollow Square & Rectangles

Solid Square & Rectangles

Trapazoid Seals

Bumpers Solid

Bumpers Hollow

C Channels

L Seals

Bulb & T Seals

Round Channels

T Seals

H Channels

Grip Seals

Extrusion Dies

Ames Rubber Manufacturing has the ability to create custom profile extrusion dies to your print or sample. We can also quickly fine-tune existing extrusion dies to your evolving specifications.

Processes

Extrusion Lines

We have 12 Rubber Extrusion lines with both hot and cold feed extruders ranging in size from 1″ to 12″ die faces. This range of extruders gives us the ability make very small to very large profiles to suit your sealing requirements. Some of these lines also have in-line curing and cutting stations for further cost savings.

Pole Curing

For precision tolerances in tubing and washers, we can extrude, wrap and pole cure tubes prior to OD grinding. Normally for Precision lathe cut requirements.

Steam Autoclave Curing

Our 5 Steam Autoclaves range in size from 3 ft. to 50 ft. length capacities. We can steam cure in straight lengths or coil your extrusion on pans for longer lengths.

Salt Bath Curing

Our inline salt bath curing system works particularly well with silicones and EPDMs for continuous lengths and higher volumes.

Hot Air Vulcanization (HAV) Curing

Our 2 inline HAV curing tunnels are used for continuous lengths of silicone extrusion.

We can cut your extrusion using a variety of methods depending on part geometry and length of cut. Our splicing services include corner and straight splices in single and multi-cavity molds.

Solutions by Industry

- Aerospace

- Architectural

- Automotive Aftermarket

- Automotive Restoration

- Building & Construction

- Chemical Processing

- Electronics

- Food Processing

- General Industry

- HVAC

- Medical

- Marine

- Material Handling

- Military

- Oilfield & Refinery

- Rail & Mass Transit

- Refrigeration

- Robotics

- RVs and Sport Vehicles

- Pool & Spa

- Solar Panels

- Sound Studios

- Transportation

- Window & Door Seals