Lathe Cutting Services

Ames Rubber Manufacturing is an industry leader in the production of precision tolerance lathe-cut gaskets, washers and seals. These seals can be made to custom dimensions with minimal tooling costs. Also known as square cut seals; they can be used in place of O-rings in almost any static seal application, giving superior sealing properties. Let Ames Rubber Manufacturing be your one stop solution for precision Lathe cut seals.

Advantages:

- Maximum sealing surface compared to standard O-rings

- No mold flash line, voids or non-fills in the seal

- No concave edges or (“hour glassing”) vs. die-cut products

- Flat and parallel cut surfaces

- Economical alternative to die cut or molded gaskets, washers and seals

- Precision molded tubes available for ultra-close tolerances

- Extruded and pole cured tubing for high volume production

- Mandrel built tubes for large diameter production

- Cuts from .010″ thick and up

- Large washers and Seals – Up to 16″ in diameter

- Precision dimensional tolerances to .003″

- Chamfered and beveled cuts

- Plastic washers, including PTFE

- Wide range of materials available

- Large selection of Inside Diameter (ID) tooling for cutting and grinding

- Minimal or no set-up or tooling charges

- Rapid prototypes/samples

- Flexible scheduling and large capacity for short lead times

Processes

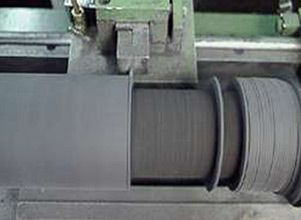

How Are Lathe Cuts Produced?

A rubber sleeve is produced by molding, extruding or mandrel-building tubes, which are then hot vulcanizing cured. The cured tube can then be precision ground to the finished Outside Diameter (OD). The tube is then transferred to a cutting mandrel, which is mounted to a lathe specially designed to cut the rubber tube to the desired seal thickness or sleeve length. Our lot control system assures full traceability for all lathe cut products throughout the production cycle.

Cost Reductions Available

One cost-reducing option includes elimination of the grinding step when an extruded sleeve is used and when extrusion tolerances are sufficient.

A second cost cutting option allows for inline profile cutting of the sleeve if tolerances allow, eliminating the lathe-cutting step completely.

Both options may be combined for maximum cost savings; however, the utilization of normal methods yield a part of excellent precision at very economical cost and with minimal part-to-part variation ensuring close tolerance repeatability.

Solutions by Item

Uses of lathe cut washers and seals include:

- Lathe cut belts (unsupported)

- Lathe cut container seals

- Lathe cut drain tubes

- Lathe cut air and liquid filter seals

- Lathe cut gaskets

- Lathe cut static seals

- Lathe cut spacers

- Lathe cut shims

- Lathe cut sleeves for roller coverings

- Lathe cut splines

- Lathe cut vibration dampeners

Solutions by Industry

- Aerospace & Aviation

- Automotive and Trucking

- Filtration

- Fluid Transfer

- General Industrial

- Industrial Batteries

- Marine

- Packaging and Container Accessories

- Plumbing/Potable Water

- Power Transmission

- Robotics

- Roller Market

- Sprayers

- Many other static and dynamic applications